Ag Panel Roll Forming Machine

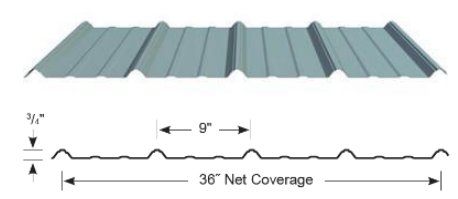

Ag metal sheeting panels are a trusted choice for roofing and siding applications, offering a combination of durability, strength, and style. With a 36-inch coverage width and reinforced ¾-inch high major ribs, these panels are designed to provide reliable performance for residential, light commercial, and agricultural projects.

Roll Forming Machine for Ag metal sheeting panels

Feature of Ag panel roll forming machine

- Production speed:0-60feet/min.

- Hydraulic shearing device

- Easy to use, simple run the PLC and then it can do the production. Here you can set length and pieces you want to do.

- Double pillar structure shearing device, shearing part more durable and powerful.

- With protective cover, more safety for operator.

Technical Parameter of Ag panel roll forming machine

| Feeding device | Several group guiding rollers |

| Steel plate welded platform to carry the sheet and feed into roll forming system | |

| Feeding width is adjustable with the handle wheels | |

| With manual cutter, avoid waste of coil. When you complete the quantity you need, you can cut the coil from the feeding inlet. | |

| Rolling shaft | Shaft material:45# STEEL |

| Shaft diameter: 80 mm | |

| Tempering treatment to prevent deformed and improve hardness | |

| Roller | 45# steel |

| Chromed treatment, improve the hardness and prevent abrasion, anti corrosion increase of service life | |

| Rolling station | 18 rolling stations |

| Work speed | 0-60feet/min |

| Machine structure | 20mm Steel plate welded structure |

| Machine basic frame | Welding with steel square pipe |

| Voltage | 220V 60HZ 3P |

| Work power | 5.5 kw |

Here are more details of the rolling forming machine:

As to the decoiler, manual decoiler and automatic hydraulic decoiler are available.

As to the stacker, you can choose length and type according to your working area space and real need: