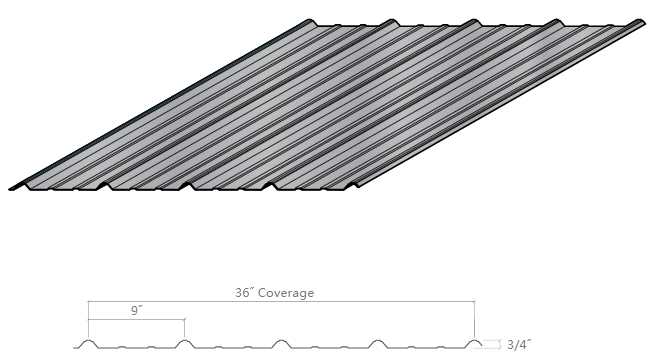

26-29 Gauge Ag Panel Roll Former

Available in 29 or 26-gauge steel, Ag panel metal sheeting panels are designed to withstand various environmental conditions while maintaining their aesthetic appeal. Available in a wide range of colors, these panels give you the flexibility to complement any building objective, making them an ideal solution for new construction projects of various sizes.

Ag panels are easy to install, reducing labor time and costs while ensuring a secure and professional finish. Their lightweight yet robust construction makes them an efficient and cost-effective choice for any roofing or siding needs.

26-29 Gauge Ag panel

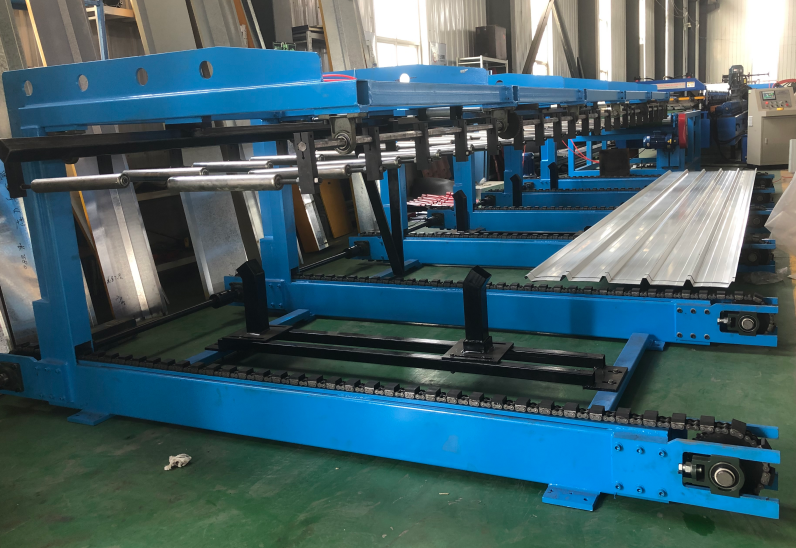

Roll Forming Machine for 26-29 Gauge Ag panel

Feature of 26-29 Gauge Ag panel roll forming machine

- Production speed:0-120feet/min. We can customize the machine according to your requirement.

- Hydraulic shearing device

- Motor power: 7.5KW+4KW

- Double pillar structure shearing device, shearing part more durable and powerful.

- With protective cover, more safety for operator

Technical Parameter of 26-29 Gauge Ag panel roll forming machine

| Feeding device | Several group guiding rollers |

| Steel plate welded platform to carry the sheet and feed into roll forming system | |

| Feeding width is adjustable with the handle wheels | |

| With manual cutter, avoid waste of coil. When you complete the quantity you need, you can cut the coil from the feeding inlet. | |

| Rolling shaft | Shaft material:45# STEEL |

| Shaft diameter: 80 mm | |

| Tempering treatment to prevent deformed and improve hardness | |

| Roller | 45# steel |

| Chromed treatment, improve the hardness and prevent abrasion, anti corrosion increase of service life | |

| Rolling station | 16-19 rolling stations |

| Work speed | 0-120feet/min |

| Machine structure | 20mm Steel plate welded structure |

| Machine basic frame | Welding with steel square pipe |

| Voltage | 220V 60HZ 3P |

| Work power | 7.5 kw servo motor |

Here are more details of the 26-29 Gauge Ag panel rolling forming machine:

As to the decoiler, manual decoiler and automatic hydraulic decoiler are available.

As to the stacker, you can choose length and type according to your working area space and real need: